Still have a question? Please contact us here

Eliminate unnecessary maintenance

Plan maintenance months in advance based on service history, ensuring that maintenace only occurs when required.

Hose life depends on the quality of the maintenance. Sherlock OHMS can help to identify and correct issues before they result in failures or downtime.

Monitoring the performance can help to identify potential issues and allow for proactive measures to be taken to prevent downtime.

Effective stock management can help to improve efficiency and reduce the risk of stock shortages or excesses.

Setting reorder points helps to ensure that there is a sufficient level of stock to allow the smooth running of operations.

Sherlock OHMS helps to ensure that all relevant information is taken into account and that the decision-making process is fair and unbiased.

Sherlock OHMS gives accurate and complete information about the movement of offloading hoses through the supply chain.

Our CRM solution can bring many benefits to O&G companies, such as cost savings, access to specialized expertise and increased efficiency.

Keep an eye on your offloading hoses, wherever you are!

Access our secure servers from any device with an Internet connection. Your information is safe and secure and just a click away.

Sherlock OHMS offers an up-to-date understanding of the levels and movement of stock, for effective decision making process.

by optimizing maintenance, preventing failures, efficiently using available resources, and providing useful analysis and reports.

Elementary my dear Watson! Please discover below how Sherlock Offloading Hoses Management System helps you make huge cost savings.

Plan maintenance months in advance based on service history, ensuring that maintenace only occurs when required.

Flag up potential risks and hazards a lot more effectively, eliminating the cost of damage control.

Use maintenance materials more economically and never be surprised by an emergency maintenance event!

Minimize wear and tear and ensure offloading line is not forced to run beyond its expected capacity.

Hoses monitored

Ancillaries monitored

IRM & FAT certificates embedded

Month of development

Meet the devs behind our software.

Software Developer

IT Administrator

Software Developer

Webmaster

IT Manager

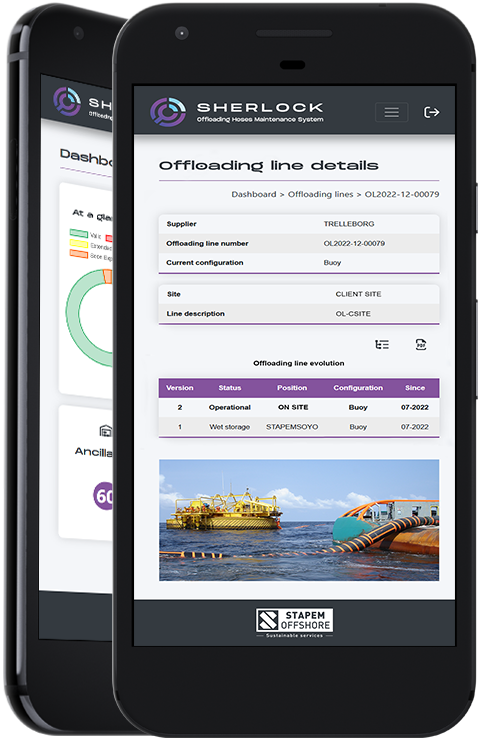

Get a sneak peek at our user interface.

Everything you need to know about our maintenance software.

An offloading hose is a specialized hose used in the offshore oil and gas industry for transferring oil or gas from a production platform to a storage facility, such as a tanker or an offshore storage terminal.

Offloading hoses are typically made of high-strength synthetic materials and are designed to withstand the harsh conditions found in offshore environments, including exposure to saltwater, high pressures, and extreme temperatures.

They are an important component in the process of transporting oil and gas from offshore production platforms to onshore facilities, and are used to ensure the safe and efficient transfer of these valuable resources.

STAPEM Group is proud to present its brand new export hose maintenance software for the oil & gas industry.

This innovative software aims to improve the maintenance and inspection of export hoses used in the oil industry, allowing for efficient planning and management of maintenance activities.

The software includes an online database for storing all information related to offloading hoses, including their characteristics, maintenance history, and inspections performed. It also allows for the planning and tracking of maintenance activities, as well as generating reports and analysis to aid in decision-making.

This software has been developed over several months in collaboration with experts in the oil & gas industry. We are confident that it will bring significant added value to our clients by allowing them to efficiently manage the maintenance of their offloading hoses.

Improved efficiency: Sherlock OHMS can help streamline maintenance processes and reduce the time and effort required to track and manage the maintenance of offloading hoses. This can lead to improved efficiency and productivity.

Enhanced safety: Sherlock OHMS can help ensure that offloading hoses are properly maintained and in good condition, which can help reduce the risk of accidents and failures that could compromise safety.

Better asset management: Sherlock OHMS can help track the condition and usage of offloading hoses, which can be helpful for planning maintenance and replacements. This can help improve asset management and reduce costs.

Increased transparency: Sherlock OHMS can provide a clear record of maintenance activities and the condition of offloading hoses, which can help improve transparency and accountability.

Enhanced decision-making: Sherlock OHMS can provide real-time data and analytics on the condition and usage of offloading hoses, which can help inform decision-making and improve resource allocation.

Sherlock OHMS provides complete access to hose data, including offloading line information, ancillaries & test results. Users can also track hose’s movement history and changes made to a line. In addition, a dashboard provides an overview of the status of the inventory.

To view your hose information, go to the “Hoses” tab in the Sherlock OHMS interface. You will then have access to a list of all your hoses, you can add filters to make it easier to find a specific hose and finally click on a hose to access a detailed view, including a list of movements and tests performed on that hose.

To consult the history of interventions on your hose line, go to the “Offloading lines” tab of the interface, select the hose line concerned, you will then find a table summarizing the interventions carried out on this line, you can then click on an intervention to obtain a detailed view of the modifications made to the line during this intervention.

Access to the Sherlock-Ohms database is secured secured a combination of various digital security measures. .

First of all, only people who have been registered by the database administrator can access the web interface. We follow a strong authentication password policy.

Secondly, each time a user want to access to the web interface, a numerical code will be sent by email to the user who has one minute to enter the code in order to validate the access.

After 3 unsuccessful accesses, the account will be blocked and only the database administrator will be able to unlock it.

Finally, let us specify that the web interface only allows consultation of data. In no case, the data can be corrupted.

Yes, it is possible to export the data of your hoses in PDF format, it is also possible to export the nomenclature of your lines in CSV format.

Yes, Sherlock OHMS has been designed to be adaptable to all types of devices, whether it be a computer, smartphone or tablet.

A CSV (Comma Separated Values) file is a type of plain text file that stores data in a table format, where each row represents a record and each column represents a field within that record. The values in each record are separated by commas, hence the name “Comma Separated Values.”

CSV files are commonly used for storing data that can be imported into spreadsheets or databases for further analysis or manipulation. They are simple to create and can be opened by most spreadsheet and database software, as well as many other types of software. CSV files can also be easily imported and exported by most programming languages, which makes them a popular choice for data exchange between different systems.

You can open CSV files using a variety of programs, including Microsoft Excel, Google Sheets, and text editors such as Notepad or Sublime Text. If you are working with large files, it is recommended to use a program such as Microsoft Excel or Google Sheets. These programs allow you to easily view, sort, and manipulate the data in the file. If you are working with smaller files or if you just need to view the data, you can open the file using a text editor.

If you encounter a problem or error with Sherlock OHMS, you can contact us using the form available on this website. It is important to provide as much detail as possible about the problem or error you are experiencing, as well as screenshots if possible, so that we can resolve the issue as quickly as possible.

Please use the contact form below and we will get back to you as soon as possible to solve the issue.

Still have a question? Please contact us here

Please send us a message using the form below.

STAPEM Offshore

4 avenue Hoche

75008 Paris

FRANCE